Water is a precious resource, and access to clean and safe drinking water is essential for the well-being of every community. However, In Kenya, Tanzania, Ethiopia, Uganda, Rwanda, and other East African nations, the expanding industrial sector and rising population are significantly straining the existing water resources. With contaminants threatening the purity of water sources, the need for advanced water treatment solutions is essential. This is where Ion Exchange’s Membrane Filtration for wastewater treatment in Kenya comes into play, offering a revolutionary approach to addressing water treatment challenges.

Challenges in Water Treatment in Kenya

According to the World Bank, about 80% of the world’s industrial and municipal wastewater is discharged into rivers and lakes without treatment, causing contamination and posing serious health risks to the population. Additionally, only 59% of the urban population in Kenya has access to safely managed drinking water services. These statistics underscore the urgent need for effective water treatment solutions. Kenya faces several challenges in water treatment, including

- limited access to clean water

- inefficient treatment processes

- high cost of implementing advanced technologies

Ion Exchange’s Membrane Filtration for Wastewater Treatment in Kenya

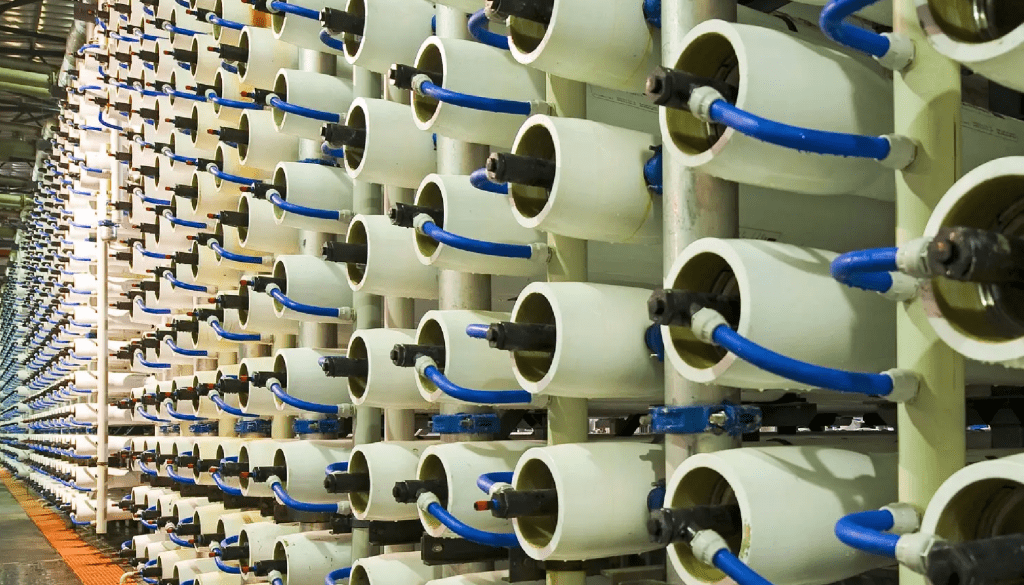

Ion Exchange, with its HYDRAMEM Membrane Filtration technologies, is capable of tackling Kenya’s water treatment challenges effectively. They are well-suited for various industrial sectors, including the automobile industry, brewery, chemical industry, food and beverage industry, paper industry, pharmaceuticals, steel industry, sugar industry, and textile industry.

- HYDRAMEM RO Membranes: These Cross-Linked Fully Aromatic Polyamide Composite membranes are offered in four categories, including low-pressure RO membranes, brackish water RO membranes, fouling-resistant membranes, and seawater RO membranes. They are designed to handle different water sources and provide efficient filtration.

- Hydramem Ultrafiltration Modules: These hollow fiber membranes are versatile and, suitable for treating brackish water, municipal waste, industrial effluents, and seawater for both potable and industrial use. With modified PES fibers and PVD fibers options, they offer flexibility for various applications.

- HYDRAMEM Nano Filtration Elements (NFE): Engineered with a hard outer shell for industrial applications. They provide high stability for temperature and pH, offering superior performance in bi-valent ion removal, brackish water softening, dye desalting, and chemical salt recoveries.

Conclusion

Ion Exchange’s Membrane Filtration technologies deliver advanced Membrane Filtration and RO/UF membrane systems for water treatment across East Africa, including Kenya, Ethiopia, Uganda, and Tanzania. Catering to a wide range of sectors such as hospitality, healthcare, petrochemicals, mining, and manufacturing industries like sugar, textiles, and food & beverage, we offer solutions with capacities of up to 250 m3/hr, ensuring cleaner and safer water.

By addressing the challenges of water contamination, limited access to clean water, and the high cost of implementing advanced solutions, Ion Exchange is making a significant impact. Ion Exchange’s MEMBRANE FILTRATION for wastewater treatment in Kenya is not just a solution but a transformation that promises a brighter, healthier future for all.